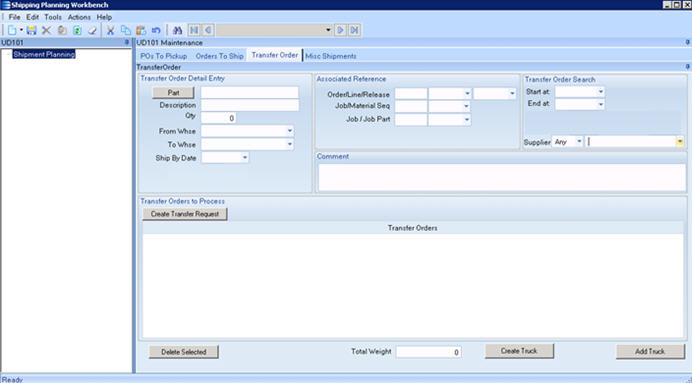

Transfer order from one warehouse to another in the same plant requires that freight costs be disbursed and added to the material cost of a part being transferred, and the material be accounted for as “in transit”. The transfer will have all of the required functions of planning a truck for any shipment, including selection of a trucking supplier, setting a due date for the shipment, selecting a part and quantity to be transferred, a ship-to warehouse (and therefore the address), a ship-from warehouse and bin, and an inventory unit of measure. Once entered, the transfer will be available on a planning grid, until selected and added to a truck.

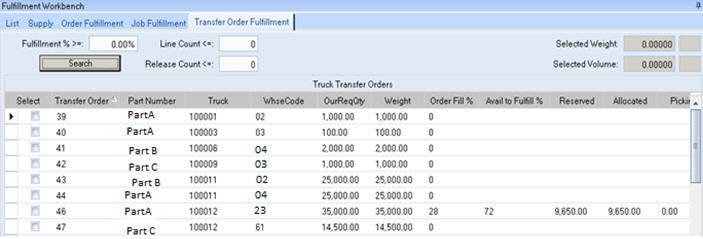

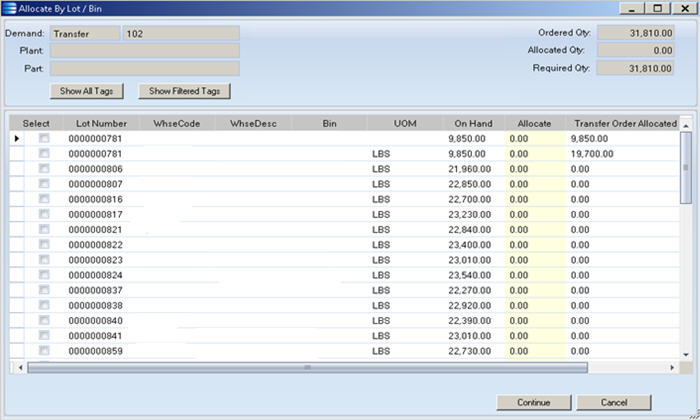

Transfer order requires that material be released for picking using the fulfillment workbench. The standard tab for transfer order allocation will be replaced with a tab for transfers that performs the required functions of 1) allocate by lot, 2)reserve and release for picking, 3) unreserve, and 4) unallocate, but can interface with information from the custom Shipment Planning Workbench, transfer order section.

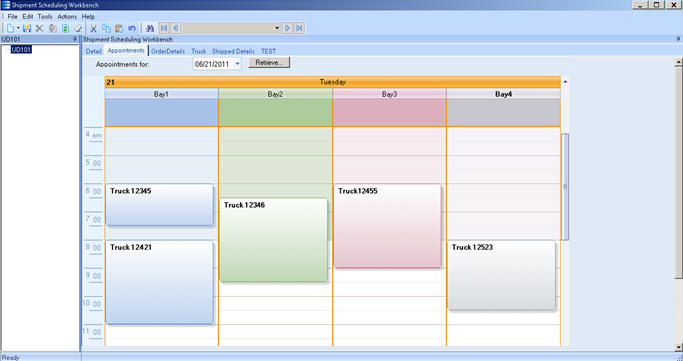

Once a truck has been scheduled (given an appointment date, start, and end time), it is available to see on the Bay schedule tab. Truck schedules can be update/created by clicking on the scheduling block. All the app information is updated through the Detail tab and reflected on the Appointments tab. When a new appointment is created, the Appt End Time will be defaulted 30 minutes after the Appt Start Time.

On Shipment, the inventory is transferred to an inventory location, “In Transit”, which is non-nettable.

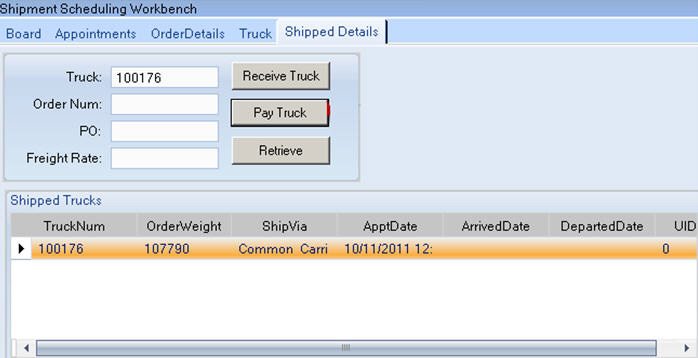

A receive truck button will be added to the shipped truck display, to process receipt transfer orders. A truck will be selected in the grid, and receive truck clicked. This will calculate the disbursed per unit freight cost by weight (freight charge / total weight of truck), and this landed cost will be added to the current cost of each transferred part/lot. After cost adjustment, a bin to bin transfer will be processed, from the in-transit location of the lot to the primary bin of the destination warehouse.

Screen examples:

Shipping Planning Workbench

Shipping Scheduling Workbench – Truck

Shipping Scheduling Workbench – Appointments

Fulfillment Workbench

Allocate By Lot/Bin

Shipment Scheduling Workbench – Shipped Details