Standard Epicor Software includes a ‘Kanban Receipts’ form which is used to identify Kanban jobs and indicate the part, scrap, and non-conformance quantities to produce such job. When the Kanban receipt is saved, the Kanban job is automatically completed and closed to minimize overhead costs. It also includes any subassembly that uses bills of material (BOMs). A specific customer’s business model requires for this form to be able to maintain and track which machines were used, the times of day at which pallets being transacted are actually completed, and the times of day at which the previous pallet was completed through production. A custom software solution was created for this purpose with several changes made to support the requirements of the customer.

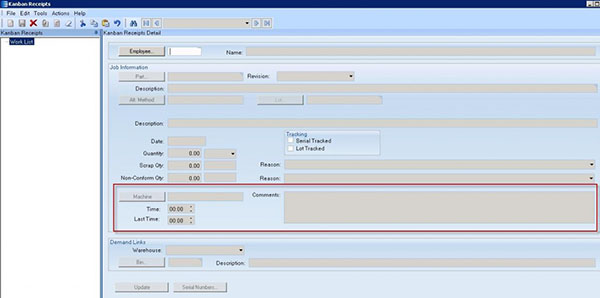

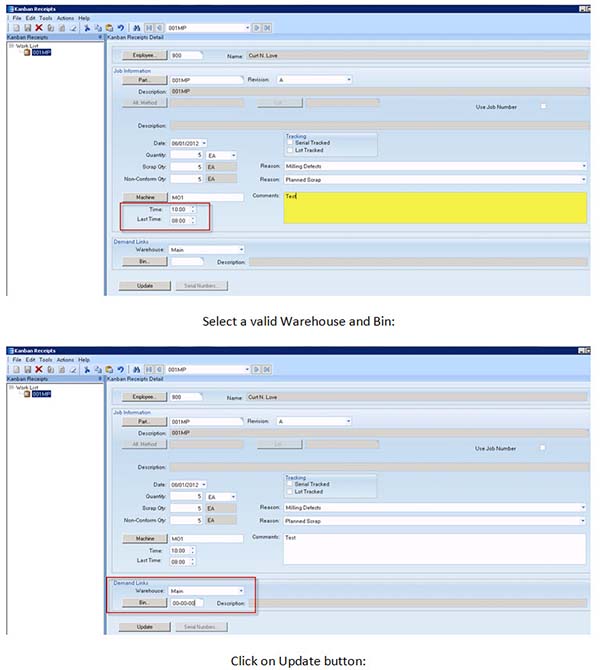

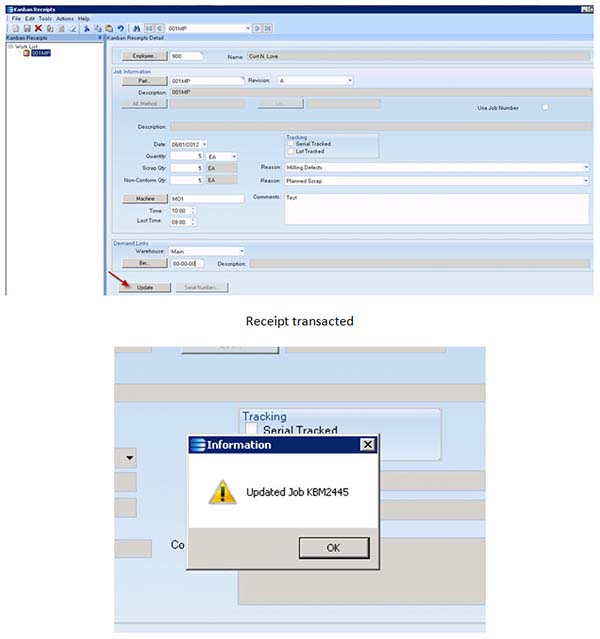

An update has been made to the ‘Kanban Receipt’ UI. The following fields were added:

- Machine - A required field. This field shows values related to the receipt. This is defined as a User Code and default is defined by the logged company, used to track the machines.

- Time - A required field. Defaults to current system time and is updateable by the user. This field represents the time of day a pallet being transacted was actually completed. (In cases where there was a delay between completion and transaction, the field is updateable)

- Last Time - A required field. Defaults to current system time and is updateable by the user. It represents the time at which the previous pallet was completed through production, and is used to calculate overall production processing time.

- Comments - A free text field for any applicable comments to be saved with the receipt, not required

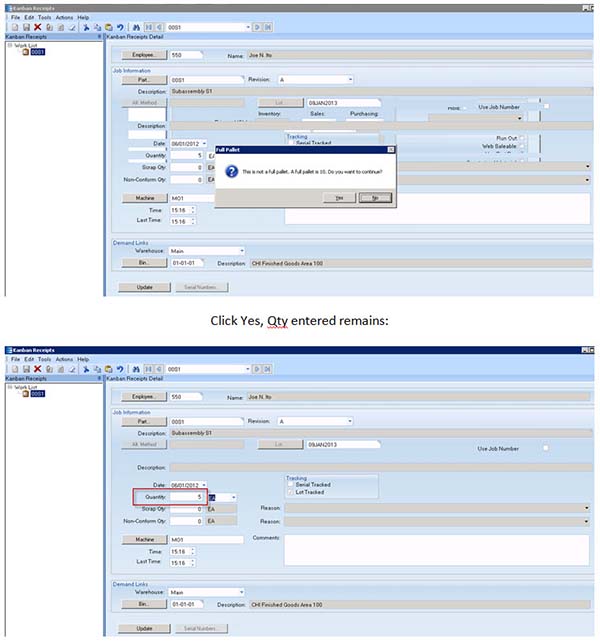

If the Qty field is updated to a quantity that is less than the value in the per container field, a message is displayed, “This is not a full pallet. A full pallet is N. Do you want to continue?”, where N = the value of Per Container in the part master. On Yes, the message clears and the data saved is entered. On No, the save is aborted, and the quantity value is refreshed:

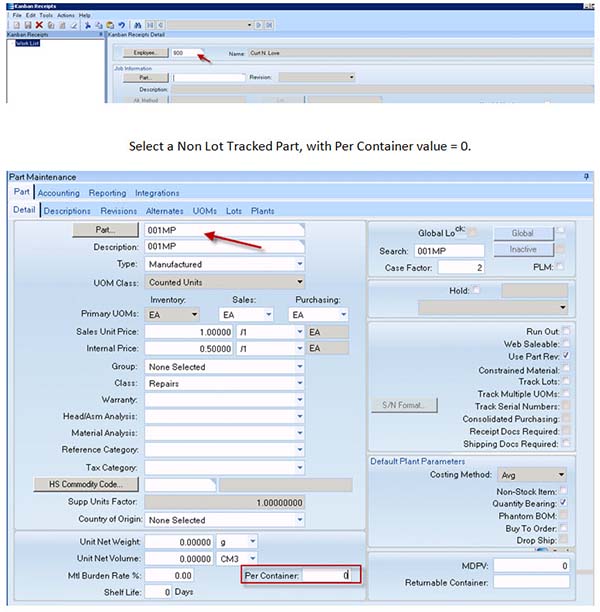

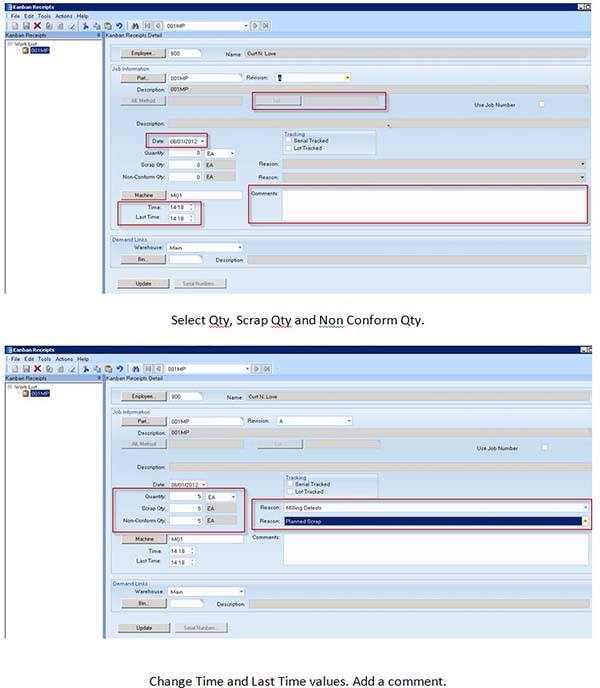

For non-lot tracked parts, the lot number field and button are disabled. For lot tracked parts, the Lot Number is calculated as system date + an Offset with format ddmmyyyy. The Lot Number field is not updateable by the user, and the Lot Number Search button is disabled, so a lot number cannot be assigned by the user at all:

Select a Production Employee.

Lot number field and search button remains disabled, lot number value = “”, date = today, Time and Last Time fields defaulted to current hour: minute, comment field enabled.

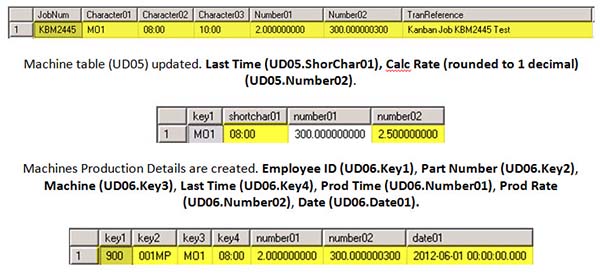

Part Tran is updated with information from Machine ID (PartTran.Character01), Time (PartTran.Character03), Last Time (PartTran.Character02), Calc Production Time (Time – Last Time) (PartTran.Number01), Comment (PartTran.TranReference).